Ministry of Agriculture and Rural Affairs: In order to prevent and control key diseases such as African swine fever, pig farms should consciously close their farms and reduce foreign exchanges.

The website of the Ministry of Agriculture and Rural Affairs released "Key Technical Measures for Strengthening the Management of Winter Pig Raising" on November 2: With the change of seasons, the weather gradually turned cold and the temperature in some areas dropped by more than 10℃. In order to reduce the impact of weather changes on pig production, entrusted by the Animal Husbandry and Veterinary Bureau of the Ministry of Agriculture and Rural Affairs, the national expert group on pig industry technology system put forward the following five technical measures for the reference of farmers.

First, do a good job in the prevention and control of key diseases such as African swine fever

African swine fever virus likes cold and heat, likes tide and fears dryness, and the sudden drop in temperature has created favorable conditions for the spread of African swine fever virus. In order to prevent and control African swine fever and other diseases, pig farms should improve the biosafety system, consciously close farms, reduce foreign exchanges, and effectively prevent the introduction and spread of the epidemic.

First, strengthen the monitoring of abnormal pigs. All manifestations: elevated body temperature, diarrhea/bloody dysentery, vomiting, salivation, anorexia/anorexia, redness on the body surface, bleeding in the mouth and nose, bleeding in the abdomen, neurological symptoms, etc., should be sampled. Samples must be refrigerated or frozen as soon as possible after collection, and sent for inspection in time.

Secondly, do a good job in the daily management of pig farms. Reduce the frequency of staff entering and leaving the field; The site is relatively closed, and irrelevant personnel are prohibited from entering and leaving the site; Personnel enter the field to take a shower, change clothes and shoes, and articles are fumigated and washed before entering the field, and prohibited articles are prohibited from being brought in; Carry out secondary decontamination before the vehicle enters the site; The feed is put into use as soon as possible, and the feed packaging can be disinfected during the transition period, and then fumigated overnight after being put into the material warehouse; Minimize the number of people entering and leaving fields as much as possible, and cross-use of tools in different fields is prohibited; Different areas are equipped with different clothes and shoes, and the clothes and shoes are changed in and out of the unit; Animals such as dogs, cats, chickens, ducks and geese shall not be kept in the field, and the prevention and expulsion of stray dogs, cats, rats, flies and mosquitoes shall be done well; Standardize the treatment of dead pigs, minimize the breeding of flies, monitor the temperature, and close the area to avoid dogs, cats and mice; Cultivate the skills of pig breeders to identify abnormal pig farms, establish basic biosafety awareness, and select appropriate staff to train sampling skills; Strengthen the inspection and supervision of technicians and background managers on the daily behavior of pig farm keepers.

Third, do a good job in prevention and control of common and frequently-occurring diseases. Considering the sudden drop of temperature, the low temperature and high humidity environment can easily induce many common frequently-occurring diseases, including: pig respiratory diseases (mycoplasma pneumonia, pleuropneumonia, etc.), gastrointestinal diseases (colibacillosis, infectious gastroenteritis, epidemic diarrhea, etc.) and various skin diseases (mold disease, scabies, staphylococcosis, etc.). The control of respiratory diseases should start with eliminating pathogens, improving the environment of pig farms and strengthening feeding management. Gastrointestinal diseases are usually treated by rehydration, antidiarrheal, dehydration and acidosis prevention. Tannin, medicinal charcoal or bismuth subnitrate can be used for astringency and antidiarrheal treatment, and antibiotics can also be used appropriately to prevent secondary infection. With regard to the prevention and control of infectious gastroenteritis, epidemic diarrhea, swine flu and other infectious diseases in pigs, on the one hand, it is necessary to prevent the temperature of piggery from changing too much, and the ideal state is to control it within 2℃/ hour and prevent thieves from invading; On the other hand, it is necessary to carry out immunization and monitoring of pig infectious diseases such as foot-and-mouth disease, infectious gastroenteritis, epidemic diarrhea and swine flu, and do a good job in all-in and all-out management and empty column disinfection.

Second, do a good job in keeping the pig house cold and warm.

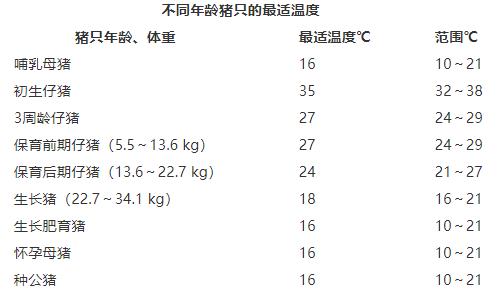

Thermal insulation and ventilation are the key to pig farm management in the season of sudden temperature change. Temperature is an important environmental factor affecting the growth of pigs. Pigs of different days have different adaptation ranges to temperature stress, that is, the optimal temperature for pig growth and development, which can be estimated by the following formula: t =-0.06 w+26, for example, the optimal temperature for 20 kg piglets is t =-0.06× 20+26 = 24.8℃ (t is the optimal temperature; -0.06 is the optimum temperature coefficient; W is the weight of the pig; 26 is the optimum temperature constant), and the following table lists the optimum temperature range of pigs at different ages. In response to the sudden drop in temperature, farms should first ensure that the doors and windows of pig houses are intact and prevent thieves from invading; Ensure that power supply, water supply, thermal insulation and other facilities are normal, focus on thermal insulation of piglets in delivery room and nursery, and create a warm and comfortable microclimate in pig house. Piggery buildings in southern China pay more attention to ventilation and cooling, and the ceiling insulation is poor. In order to obtain good ventilation effect, the ceiling is higher from the ground, which is not conducive to the temperature increase in the house. In order to cope with the sudden change of weather, a temporary two-story shed (generally 2 meters high) can be built above the pig bed in the shed, and infrared insulation lights, insulation boards, warm air stoves and other measures can be used to ensure the piglet heating in the delivery room and the temperature of the nursery.

Third, strict implementation of scientific disinfection procedures

African swine fever, pseudorabies and other viruses have strong resistance to the external environment, and their resistance to different disinfectants is also different, especially when the temperature suddenly drops, the disinfection effect is greatly reduced. Disinfection is a key link in the prevention and control of African swine fever and other diseases, and disinfection should be done from the following aspects.

Personnel disinfection. Personnel are one of the main media to bring pathogens into the pig farm, and all personnel entering the pig farm must be strictly disinfected. A staff bathroom should be set up at the gate of the pig farm. All personnel entering the farm should take a bath and change their clothes and shoes in the living area before entering the pig farm. Workers entering the production area from the living area also need to take a bath and change clothes and shoes in the production area. Clothes and shoes in the living area and the production area are strictly prohibited to be mixed. A pedal disinfection basin and a hand-washing basin should be set at the entrance of the pigsty. Workers should step on the disinfection basin and clean their hands when entering and leaving the pigsty.

Vehicle disinfection. The pig farm should adopt measures such as installing centralized feeding tower and upgrading the pig farm access platform to ensure that off-site vehicles do not enter the pig farm. Vehicles that really need to enter the site must be strictly cleaned, disinfected and dried.

Sterilization of materials. A one-way material disinfection room should be set at the entrance of the pig farm and the production area, and the disinfection room should be sealed well. For small materials, 10ppm ozone fumigation and disinfection can be used for more than 30min; Materials that need to be preserved at low temperature, such as vaccines, can be removed to the minimum package and then soaked or wiped with mild disinfectant for disinfection; For mobile phones, computers and other electronic equipment and precision instruments, they can be wiped with chlorine preparation first, and then disinfected at 65℃ for 30min. For large materials that cannot enter the disinfection room, a disinfection machine can be used for spraying disinfection or manual wiping disinfection.

Environmental disinfection. For the environment in office buildings and dormitory buildings, 0.5% peracetic acid or 1000 mg/L chlorine-containing preparation can be sprayed once in the morning and once in the evening. No-wash disinfectant is placed in offices, aisles, restaurants, transfer windows, bathrooms, etc., and hand disinfection is carried out at any time. For the pigsty corridor in the production area, the special person in the production area is responsible for spraying it with 2% caustic soda every three days; 2% caustic soda or glutaraldehyde is sprayed once a day for the passages and aisles in the site; The duty room and appliances in the house are sprayed and disinfected once a day.

Disinfection of piggery. It is best to implement the "all-in and all-out" production mode in modern scale pig farms, so as to carry out thorough terminal disinfection for each pig house. After all the pigs are transferred out, the pigsty must be thoroughly cleaned to remove all organic matters before disinfection, and then disinfected twice with effective disinfectants such as glutaraldehyde and sodium hypochlorite. Pay attention to using different disinfectants for disinfection twice.

Drinking water disinfection. Conditional pig farms can install water purification equipment to ensure the hygiene and safety of drinking water. Pig farms that cannot install water purification equipment can add disinfectants such as bleaching powder or sodium hypochlorite to their drinking water every week to eliminate pathogenic microorganisms in the water, and the drinking fountains or sinks should also be disinfected regularly. For corrosion-resistant equipment, try to use caustic soda or other disinfectants with strong bactericidal effect.

Disinfection of waste. Fetal membranes, stillbirths, etc. shall be collected, transported and treated harmlessly by special personnel. Pay attention to prevent cross-contamination in the process of collection and transfer, and the transfer tools shall be cleaned and disinfected in time and placed in the specified place. Personnel who enter the house to deal with dead pigs must wear disposable protective clothing, masks, hoods, gloves and water shoes, transport the dead pigs with special tools, and clean and disinfect them in time after treatment.

In addition, in the pig sales process, we must do a good job in personnel control. After selling pigs, we should thoroughly clean up the organic substances visible on and near the pig platform, spray foam cleaner for 30min, rinse and dry with clear water, and spray disinfectants such as caustic soda and chlorine preparation for disinfection. In order to avoid the cross between the people in the field going out to see the pounds and the pig collectors, it is best to install a physical partition on the pig outlet.

Fourth, properly adjust the diet formula and do a good job in daily feeding management.

First, appropriately increase the nutritional intake of pigs. Under the condition of low temperature environment, the maintenance needs of pigs increase, so the demand for nutrients such as energy increases. There are two ways to increase the nutritional intake of pigs: adjusting the feed formula, appropriately improving the energy level of the feed, such as adding 10% ~ 15% of corn or 2% ~ 3% of vegetable oil to the feed, and adding some multivitamins, amino acids and compound enzyme preparations with anti-stress and anti-oxidation abilities; Appropriately increase the feeding times, in winter, the days are short and the nights are long, and the pigs spend a long time on an empty stomach at night, so as to increase the daily feed intake.

Second, cold feed has a great influence on pigs in winter, so try to feed dry powder or warm water mixture, and provide clean warm water for pigs to drink freely if possible.

Third, it is necessary to strengthen management, especially to strengthen the management of suckling piglets, so that piglets can eat colostrum in time and feed suckling pigs in advance to promote their growth and development. With the strengthening of feeding management, the physique, cold resistance and disease resistance of pigs will be enhanced accordingly.

Taking warm water for pigs to drink, the water temperature is above 20℃, which can reduce diarrhea and body temperature loss of pigs. It is a good way to supply warm water to the integrated water tank of coal stove. The coal stove is in the water tank, which is connected with the water tank. Both the outer wall of the water tank and the smoke exhaust pipe passing through the water tank can heat the water in the water tank, which not only has high utilization efficiency of coal, but also has good heating effect, and is worth popularizing in cold areas such as Northeast China, Northwest China and North China.

At the same time, when the temperature is low, the supply of concentrate in the feed should be increased by 15% compared with usual. If possible, warm and wet plates can be used to feed, and the energy of the diet should be increased at the same time. It is suggested that the energy of the diet should be increased by 0.1 ~ 0.3 calories on the basis of the previous one in extremely cold season, and attention should be paid to the preparation of the diet to increase palatability so as to increase the feed intake. Supplementing mineral elements and vitamins, especially in sow and piglet stage, can increase the content of mineral elements in feed appropriately, and supplement silage and carrots evenly to prevent vitamin deficiency caused by long-term closure and short-term sunshine, causing skin diseases or reproductive obstacles.

Five, do a good job in breeding pigs, the implementation of self-breeding.

Self-propagation and autotrophy are conducive to preventing the introduction of foreign epidemic sources. If introduction is really necessary, relevant disease detection should be done in advance to prevent the purchase of sick pigs and recessive infected pigs. After the breeding pigs arrive, they are kept in isolation for 40-60 days, immunized according to established procedures, and can only be kept in mixed groups after it is confirmed that there is no epidemic disease.

Reporting/feedback